-Lists factors preventing approval of herbal formulations

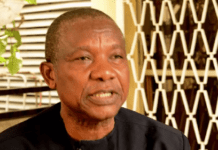

The Director General, National Agency for Food and Drug Administration and Control (NAFDAC) Prof. Moji Adeyeye, has said Nigeria cannot manufacture or export vaccines, until NAFDAC attains the World Health Organisation’s Maturity Level 3 (ML3) in the Global Benchmarking Tools (GBT).

Stressing that vaccines manufacturing is a highly technical venture which involves a wide complexity of human and material resources, as well as technology, Adeyeye however assures Nigerians of the capability of NAFDAC to meet the global standard soonest, noting that the agency has made advanced preparations in readiness for WHO’s GBT assessment.

She further disclosed that the attainment of ML3 by the regulatory body is just the first step of requirements for manufacturers and investors hoping to go into vaccines production in the country, as such are also required to have a GMP-compliant facility and register the vaccine with NAFDAC before they can proceed to express interest for WHO’s prequalification of their vaccines.

The NAFDAC boss made the disclosure to Pharmanews in an exclusive interview, while expressing confidence in government’s support to aid the agency in securing the GBT approval in no distant time.

She said: “We are positively hopeful of that attainment, as government has assisted us in many ways to reach that goal. When that happens, an investor hoping to go into vaccine production would have to have a GMP compliant facility; the vaccine must first be registered by NAFDAC before those manufacturers can express interest for WHO’s prequalification of their vaccine.

“It is quite a long process that has to do with WHO, but as a National Regulatory Authority (NRA), we will guide the industry in the areas of capacity-building for the submission of documents called Common Technical Document (CTD) dossier preparation, Good Manufacturing practices (GMP) principles, and Corrective Actions, Protective Actions (CAPA) implementation.”

Asked about the percentage of pharmaceutical companies which can produce viable COVID-19 vaccines in Nigeria, she said despite the economic situation in the country, there are still about 15 to 20 percentage of manufacturers with the capabilities to produce COVID-19 vaccine.

“But of course, more can be achieved with the provision of appropriate infrastructure and reasonable investment by public and private sectors in the pharma industry,” she said.

Adeyeye further hinted on the efforts of NAFDAC to upscale local manufacturing and discourage over-dependence on drug and vaccine importation, through generation of data from survey to enhance the formulation and implementation of government policies in favour of local manufacturers.

According to the DG: “A GMP roadmap was conducted to assess the level of GMP compliance of each pharmaceutical manufacturer in Nigeria and work with them in meeting their needs towards reaching WHO certification.

“The impact of the GMP roadmap exercise has been tremendous. With our current efforts at ensuring that quality standards related to Good Manufacturing Practices are enforced, our local manufacturers are taking up the challenge of erecting new facilities that will meet GMP requirements.”

Speaking on why several herbal preparations submitted to the agency have not been approved, Adeyeye mentioned inability of manufacturers to conduct clinical trials, failure to adhere to good clinical practice, failure of manufacturers to submit necessary documents along with their applications, and lack of ethical clearance, among others.

She, however, noted that two applications made it through screening and one has been given approval to conduct clinical trial while the second was given compliance directives which the company was yet to respond to.

According to her, “To establish efficacy of herbal medicines for treatment of diseases, they have to conduct clinical trials, which is an international quality assurance procedure for studies carried out on human participants. This means that Good Clinical Practice (GCP) must be applied at all stages of clinical trials to ensure that quality and ethical requirements for clinical studies are met.

“The first step is the application to conduct the trial for which we have published all guidance documents on our website to guide the clients on a stepwise approach. That aside, we also carried out many trainings on GCP.

“Unfortunately, some clients just submitted samples of their products without the accompanying necessary documents, like the protocol, which is a document that gives description of how the trial will be conducted, the objectives of the study, design, methodology, safety considerations, sample size, integrity of data collected and so on.

“Many others were rejected because of safety-related issues of their products. Part of issues key to the assurance procedure in the conduct of trials is ethical clearance for the study, which assures that the trial subjects are protected throughout the study conduct. Many of the applicants did not have ethical clearance.

“Notwithstanding, two applications made it through screening and one has been given approval to conduct clinical trial while the second was given compliance directives which the company is yet to respond to.”