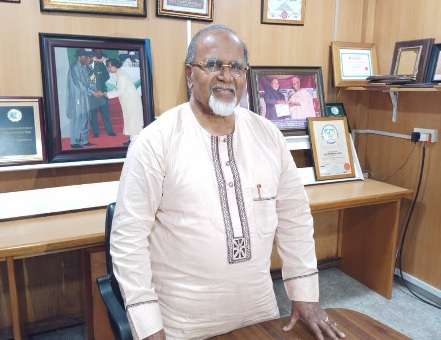

Mr Varkey Verghese is the managing director and chief executive officer, Jawa International. In this interview with RANMILOWO OJALUMO, he recounts Jawa’s success story, so far, as well as its immediate future plans. He also dismisses the notion that locally made drugs cannot favourably compete in the international market. Excerpts:

Jawa has recorded some achievements in the past few years. Can you briefly share with us the success story of the company, so far?

Well, we started Jawa International 24 years ago. We had a humble beginning, with five products in our basket; but today, we have been able to expand our activities, and we now have more than 120 products.

We have also divided these products into three divisions. The first comprises OTC products. The second consists of ethical products – which are prescription products, managed by Annie Pharma Limited. Some of the products are manufactured locally and some are from overseas. The third division deals with animal care – that is, veterinary drugs. It is handled by Kattle Care Limited. These are the areas that we have grown into in the last 24 years.

What is the company’s next move?

Our next move is to upgrade our manufacturing facilities, so as to meet the standard set by the National Agency for Food and Drug Administration and Control (NAFDAC). We are embarking on capital intensive projects in our existing plant and we are also setting up a new plant of beta-lactam manufacturing. These are the things we are doing now.

In addition to that, we are adding more products to our basket because we have created a good marketing network in Nigeria. We have six branches in Nigeria to cover all the geopolitical zones. We have one in the northwest that is based in Kano; we have one in the northeast that is based in Yola; we have one in Suleja that covers the middle-belt, and we have one in Enugu to covers southeast; so also in Aba. We have in Ibadan, as well as in Lagos.

In all these places, we have warehouses that are being managed by a manager and medical representatives. So, we need more quality products to fill the market and sustain our operation.

What is the current state of the Beta-lactam factory?

The factory is 85 per cent completed. The remaining 15 per cent will be completed, hopefully, before December, this year, because some consignments are already on the way and, as soon as they arrive, technicians will come to do the necessary installation.

By the grace of God, the remaining work in the factory will be completed before the end of December this year. By 2024, Beta-lactam products from the factory will hit the market.

As the CEO of a manufacturing company in Nigeria, how would you describe the past seven months of the year 2023?

The past seven months have been a great disappointment and I am sure this is not just for us at Jawa International but also for other companies in the country. The naira redesign, or change of colour, and the non-availability of cash really crippled the purchasing power of many Nigerians. This was preceded by fuel scarcity and then the elections came. The last seven months have really been tough.

Is there anything at all you consider good within the past seven months?

Well, the good thing that I think has happened in the course of the years is the new government that came on board and then made some radical changes. Though it may be bitter to start with, I am sure that, in the long run, it will help the country.

The fuel subsidy that was removed is a necessity. Within the period, fuel consumption has reduced by about 30 per cent, according to information in the public domain, which is a big saving to the country. We will all get used to it.

Many people are moving around with luxury cars and SUVs, but with this increase in the price of fuel, people will find it a bit difficult to do so. If you ask me, to be frank, the government should encourage people to start using two-wheelers. People should start using two-wheelers to the office. In countries like the UK, people go to the office by public transport. 90 per cent of people don’t take their cars to work.

Cycling is another way to go to the office; it is a healthy endeavour. I think it is high time we changed our mentality and orientation in the country.

What is your take on the forex unification policy?

It is also a good policy because a lot of corruption is taking place through the forex exchange. Although it will increase the price of products now, I think it will be a good move in the long run.

As the CEO of Jawa, what is the key thing that has been helping you to move on over the years?

It is passion; passion to succeed. Whatever you are doing, you must have passion for it. It is passion that will help you to excel. The desire to excel in whatever you are doing is also key.

What do you think stakeholders in the Nigerian pharmaceutical space need to do to move the industry to greater heights?

Stakeholders, especially those in manufacturing, need to raise their standard in terms of their production facilities; that is the only way they will be able to come up with quality products. Stakeholders have to look inward and then develop modern facilities so that we can compete favourably with imported products.

The importers, on the other hand, should look inward and start manufacturing locally. They should not just be importing but they should invest in local manufacturing. This is very important and this is why I must commend the 5+5 policy of NAFDAC, which is meant to encourage local manufacturing.

What do you think the Nigerian government needs to do to also move the industry forward?

The Nigerian government needs to, as a matter of urgency, encourage local manufacturers in different ways. Many foreign donors are coming to support the Nigerian health sector. One way they do this is through the provision of drugs to hospitals and health centres. While this is a good move, the donors should buy those drugs locally. For instance, if they want to help in fighting malaria in Nigeria, they will provide antimalarial drugs to the hospitals and health centres. Those antimalarial drugs should not be imported. They should be bought from local manufacturers.

The notion that the drugs manufactured locally are not up to standard is not true. Drugs manufactured in Nigeria are of good quality and they meet international standards. Patronising the local manufacturers will help to create more jobs.

Another important thing is the health intervention fund. The Buhari administration provided the health intervention fund, through the Central Bank, and I am sure some companies in Nigeria benefited from it. The current government should make such funds available.

To set up a pharmaceutical plant today that will be in NAFDAC standard, even if it is a small one, you will spend nothing less than N1.5 to N2 billion. To set up such a facility, you need a low-interest fund for a long period and this is what many countries are doing to be self-sufficient.

What is your advice to upcoming CEOs?

They should look inward, especially in some areas where we don’t have too many players – like the injectables. Upcoming investors in the pharma sector can set up an injectable factory, which will help to meet the demand of the citizens

And your professional message to the players in the industry?

My message to manufacturers in the pharma sector is that they should produce only quality products.